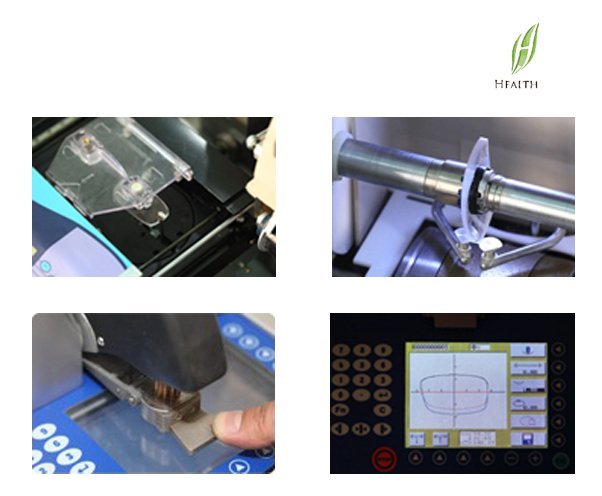

3D patternless lens edger 1. 3D scan 2.with centering device function in the same machine 3.Can grind plastics, glass and PC

Specification:

- Wide applicability:Scanning all types of spectacles frames, patterns or paddings(3D).

- Grinding wheel:Using diamond grinding wheels made in Germany,which is lasting and practical, speeding and polishing.

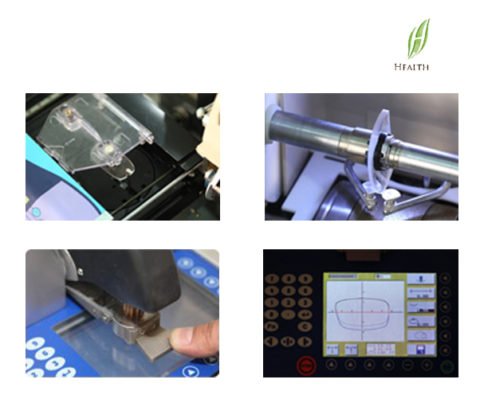

- Convenient operation: With English windows user interface,graphic combination let operation more simple convenient and easier.

- Function: Using high-precise distance measurement checking the outer and inner bend of lens, auto-grooving,smoothing polishing and safety beveling.

- Efficiency: Processing two spectacles at same time,which can improve the productivity.

- Safety: Self-checking system special to protect when error operation.

- Update: Machine software can be updated by connect computer,which guarantee machine in the leading position.

Description:

1. Easy to use, easy to maintain.

2. Fast scanning, easy to scan templates and samples.

3. The latest super-smooth professionals ground water film procedures.

4. Cost-effective, economical.

|

ADV edger configuration and options |

|||

|

Grinding wheel configuration and its functions |

ADV-E |

ADV-I+ |

ADV-II |

|

Glass rough grinding wheel |

√ |

√ |

√ |

|

PC rough grinding wheel |

√ |

√ |

√ |

|

Bevel and rimless finishing fine grinding wheels |

√ |

√ |

√ |

|

Bevel and rimless finishing buffing wheels |

√ |

√ |

√ |

|

Automatic press-sucking |

√ |

√ |

|

|

Automatic slotting groove and safe-edging beveling |

√ |

||

|

Graphic storage |

√ |

√ |

|

|

bifocal lens making software |

√ |

√ |

|

|

Graphic rotating and editing |

√ |

√ |

√ |

|

Progressive Additional Lens editing |

√ |

√ |

|

|

Software update |

√ |

√ |

√ |

Scanner:

- Self checking

- Self compensation of lens

- Scanning all kinds of lens, any ship of template or sample lens.

- Automatically 3D scanning.

- Automatically measurement of lens bending

- Scanning of lens diameter:80mm to 19mm.

Blocking:

- Standard operation interface for operator

- Color LED

- Control of screen contrast and color turn over

- Rough edging :Glass or Rosin lens and PC lens

- Finishing edging :control of shape(The top table bending beveling.

- Most after depend table bending beveling ,one half beveling, beveling of base bending

- According to the lens frame, rimless, polishing , safety beveling, grooving.

- Display of graph number.

- Acetabular of optical center.

- Automatically blocking.

- Accurate precision with acetabular pad.

- Input accuracy of PD or pupil height(0.1mm)

- PD : Horizontal millimetric decentration, monocular pupil distance, binocular pupil distance.

- Pupil height:Difference of pupil height, boxing mode of pupil height, Mix mode of pupil height.

Note:

- The machine can distinguish the input value automatically.

- Suitable to process single lens , bifocal lens, progressive lens.

- Set up different size of chuck according to the lens.

Edging;

- Self inspection.

- 3D Lens , 3D detection.

Configuration:

- Rough edging of glass lens all rosin lens or PC lens

- Finishing edging of bevelling /rimless

- Polishing of bevelling /rimless

- Self control of chuckpressure

- Control of edging pressure according to lens type

- Safty bevelling

- Storage graph:300

- Convenient to hold water

- Diameter of processign lens . MAS:80MM, Minimum for bevelling :19.9mm

- Drain pipe diameter:100mm

- Water pressure:4-7pa

Parameters:

- Outline dimensions: Length:660mm Width: 620mmm

- Hesight (cover closed):430mm

- Hesight (cover open):520mm

- Weight:78kgs

- Power supply: 220V/50hz, 110V/60HZ

- Power consumption:1000w

- Ambient Temperature :15°C-40°C

- Max Water Pressure :7 bars

- Max Pump Pressure:7 bars

- Pump Section Outlet:Supply voltage:110V/220V

- Power available: 350W

- Function Parameters:

Min Grinding Diameters: 20mm

Max Grinding Diameters:80 mm

Max Grinding Height in bevel:19.5 mm

Max Polishing Height in glass:17.75mmsoftware

The software can be updated by computer.