auto lens edger with PC wheel, The difference between LE-400 and LE-420 is: LE-420 adds beveling polishing function

According to the different materials (like glass, resin or PC), sizes, types (like round lens, small lens or right-angle lens) or shapes (like-pointy edges, plat-band, Flat edge and bevel polishing),it can edger the lens that fit for the lens frame,or same as the pattern or demo lens through the running of the machine controlled by the main electrical optical boar.

Added the automatic emendation system in this new model. It can do automatic emendation when machine start up, assure the size of lens (left and right)is uniform and improve the precise.

feature

- New design with PC function;

- Added the automatic emendation system;

- Four pieces of wheels(PC rough wheel, Glass rough wheel, ”V” wheel and Polishing wheel);

- Automatic clamping system: three kinds of presses suitable for different kinds of lenses;

- Add self-motion revise function;

- Easy to use, simple to install;

- Computer- controlled techniques ensuring the precision;

- Using the advanced technology and being big-league in china

|

|

|

|

| Auto-Clip System | Wheel Configuration | Follow-up pressure | Automatic Emendation Procedure |

| Use of third gear pressure on the lens without damage | Standard configuration of four wheels( Resin coarse grading wheel/ Glass coarse grinding wheel, V-flat edge/ sharp edges fine grinding wheel, flat resin edge/sharp edges polished wheels) | It can increase the pressure automatically through the control of procedure during the start of the grinding which can ensure that no harm to the lens | Automatic emendation of the lens size, initial zero proof reading during the start of grinding, obvious improvement of precision. |

Direction of Diagram

- soundproof cover

- carriage weight-changing lever

- template retainer lever

- carriage back lashing sensor

- power cord

- adjustable cover

- waterproof cover

- carriage

- lens clamp

- gear wheel

- operation panel

- on/off switch

- water supply pipe

- water supply cock

- pump power cord

- pump

- drain pipe

- tank

- filtrate skep

Direction of Wheel:

- a. Polishing wheel: used for polishing of flat style and beveled style for resin and PC lenses

- b. Rough grinding wheel: used for roughly grinding glass lens

- c. Fine grinding wheel: used for beveled style or flat style grinding

- d. PC rough grinding wheel: used for roughly grinding PC or resin lens

Direction of Control Panel:

- PC, CR , GL lens selector

- test switch

- chuck press selector

- frame selector

- beveling and framelss selector

- minus (-) switch

- plus (+) switch

- re-edging switch

- shift ( left ) switch

- shift ( right) switch

- start switch

- stop switch

- lens-clamping switch

- lens-loosening switch

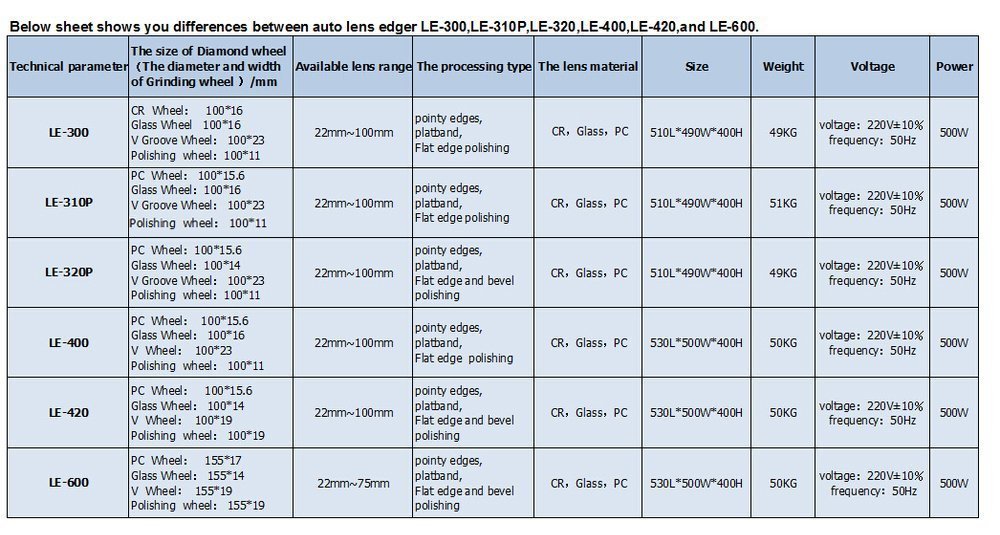

Specification:

- Diameter of processed lenses: 22mm ~100mm

- Range of adjustable measurement: -6.0mm~+6.0mm(0.05mm/step).

- Dimension of figure: 530(L)×500(W)×400(H)mm.

- Weight: 50KG.

- Electric Voltage: 220V±10%/110V±10% 50HZ/60HZ.

- Power: 500W.

- a. Polishing wheel: used for polishing resin lenses

- b. Rough grinding wheel: used for roughly grinding glass lens

- c. Fine grinding wheel: used for bevelled style or flat style grinding

- d. PC rough grinding Wheel: used for roughly grinding PC or resin lens